Current Projects

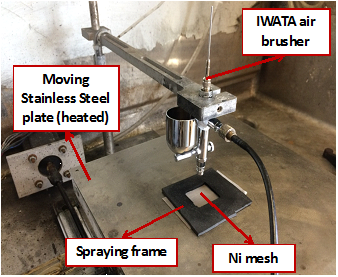

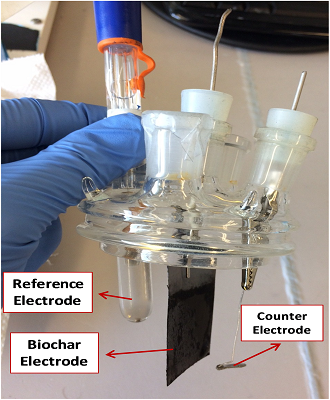

Wood-based Activated Carbon (WAC) Development for Supercapacitors

Joint project between the University of British Columbia and Cantimber Biotech Inc.

Scholar: Dr. Amir M. Dehkhoda, Post-Doc Fellow, Department of Chemical and Biological Engineering, University of British Columbia

Supervisor: Dr. Naoko Ellis, University of British Columbia

Project introduction:

Cantimber Biotech Inc. is the only Canadian large-scale manufacturer of wood-based activated carbon (WAC) for purification of water, food and pharmaceuticals. To further broaden their product applications, the current research project is focused on developing Cantimber’s WAC for high-end and niche market of making energy storage devices, known as supercapacitors. Renewability and cost-effectiveness of WAC for making energy storage devices are the major competitive advantages over commercial carbon-based material prepared from costly and complicated methods (e.g., carbon nano-tubes).

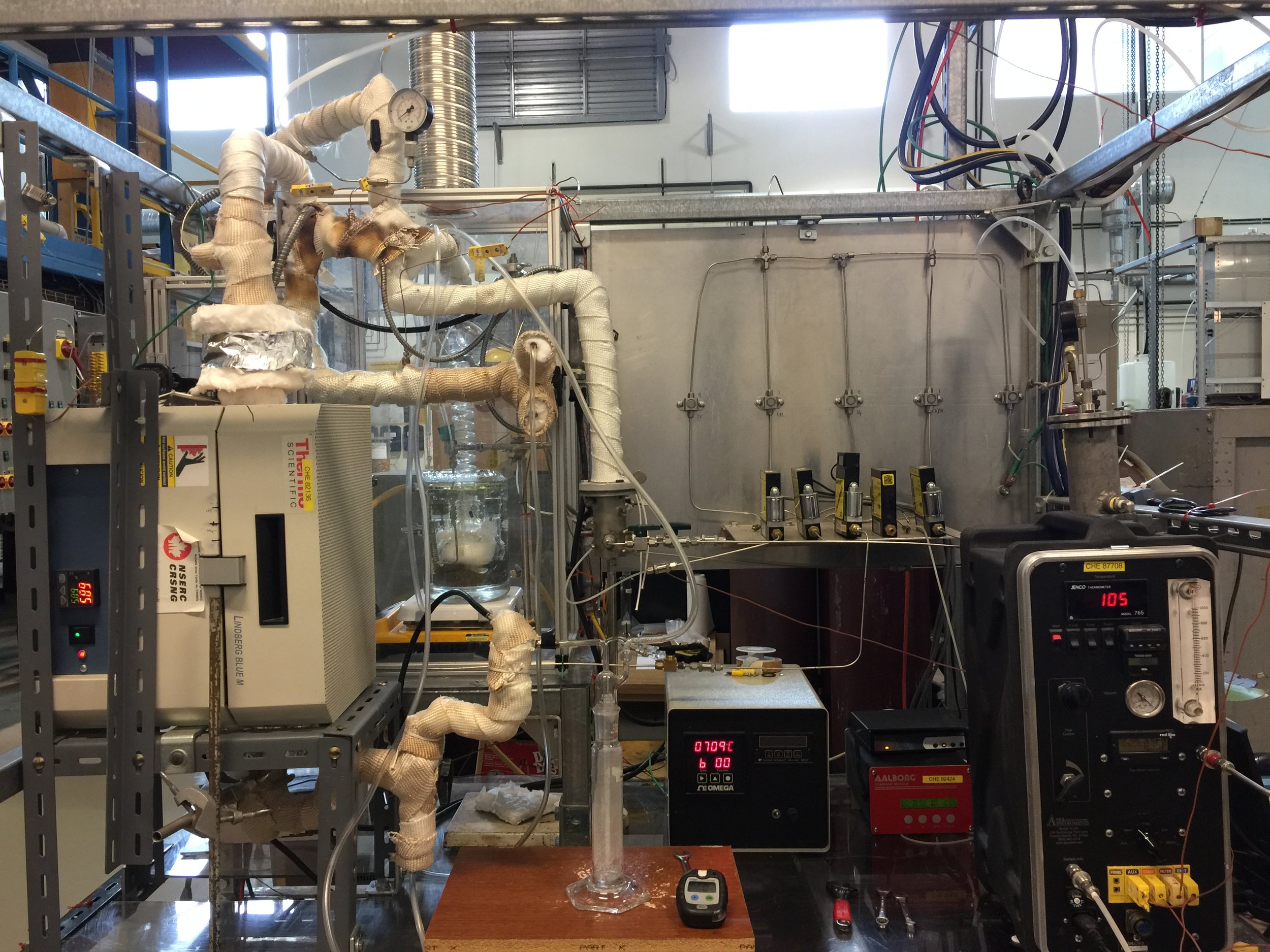

Investigation of Pyridine Synthesis in Fast Fluidized Bed Reactor

Visiting student: Shuaishuai Zhou, PhD student

Supervisor at home university: Dr. Chunxi Lu and Dr. Mengxi Liu, College of Chemical Engineering, China University of Petroleum (Beijing)

Supervisor at visiting university: Dr. Xiaotao Bi, Department of Chemical and Biological Engineering, University of British Columbia

Project introduction:

Pyridine and 3-picoline have been widely used for synthesis of pharmaceuticals and agrochemicals, benefiting from high chemical reactivity as well as biological activity. Traditionally, pyridine bases were obtained from coal tar and suffered from high sulfur content. In 1920s, large demand of pyridine and pyridine bases in the market encouraged development of new technologies for pyridine synthesis. Now, most of the pyridine bases are produced based on Chichibabin condensation process. Typically, pyridine bases are synthesized by ammonia and aldehydes in a bubbling fluidized bed reactor. However, due to the coking problems, the feed introduction device usually got stuck, which hindered the continuous operation. Besides, the back mixing in the bubbling fluidized bed reactor is severe, which reduced the selectivity of pyridine over 3-picoline. To solve these problems, a novel turbulent-fast-bubbling fluidized bed coupled reactor is proposed by the China University of Petroleum (Beijing). The main purpose of current project is to investigate the performance of this novel coupled reactor in pyridine synthesis process. A pilot scale experiment apparatus is built right beside the industrial units and experiments were carried out. Besides that, reactor modeling is required to have a further insight on the influence of operation conditions on reactor performance.

Research into the kinetic analysis of catalytic combustion for biomass torrefaction gases and vapors

Visiting scholar: Dr. Yichuan Li, Lecturer, College of Chemical Engineering, China University of Petroleum, Huadong

Hosting professor: Dr. Xiaotao Bi, Department of Chemical and Biological Engineering,University of British Columbia

Project introduction:

Torrefaction is a thermal process where a biomass feedstock is heated at 200 to 300 °C in the absence of oxygen. The main objective is to use the torrefied biomass as a fuel, which provide a marked potential way to reduce greenhouse emissions. Volatile species released during wood torrefaction are normally burned in a combustion unit to produce the heat energy needed in torrefaction units. The combustion kinetics is an important characteristic to describe the effect of the operating parameters, such as reaction temperature, heating rate and residence time, on the conversion rate of biomass-to-bioenergy. A major advantage of kinetic analysis is that the reaction rate of biomass torrefaction gases and vapors combustion can be predicted.

The purpose of this investigation is to explore the catalytic combustion kinetics of volatile species released during torrefaction of biomass by an experimental and theoretical study. The main issues are: a) investigate the behavior of catalytic combustion for volatile species by thermo-gravimetric analysis (TGA) and differential scanning calorimeter (DSC); b) comprehensive evaluate the performance of catalytic combustion; and c) establish the kinetic model of catalytic combustion for biomass torrefaction gases and vapors.

Syngas Methane reforming and Characterization of Solid Fuels

Visiting student: Xiaosu Wang, Master's student

Supervisor at home university: Dr. Guangqing Liu, College of Chemical Engineering, Beijing University of Chemical Technology

Supervisor at visiting university: Dr. Paul Watkinson, Department of Chemical and Biological Engineering, University of British Columbia

Project introduction:

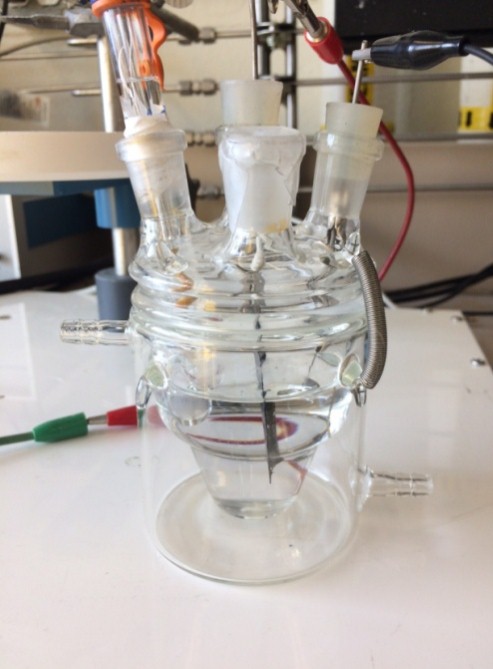

One project designs a lab-scale fixed bed reactor for syngas methane reforming and water shift reactions. The syngas produced from the dual-bed biomass steam gasification will be used for Fischer Tropsch Synthesis to produce liquid fuel. This project aims to find the proper reaction conditions to optimize the syngas composition and H2/CO ratio, in order to increase the synthesis efficiency and liquid fuel yield.

The other project is characterization of solid fuels by thermogravimetric analysis (TGA). Representative solid fuels ranging from biomass, coal and petcoke were used in TGA to evaluate and compare their thermal behaviors under inert and oxidizing atmosphere.

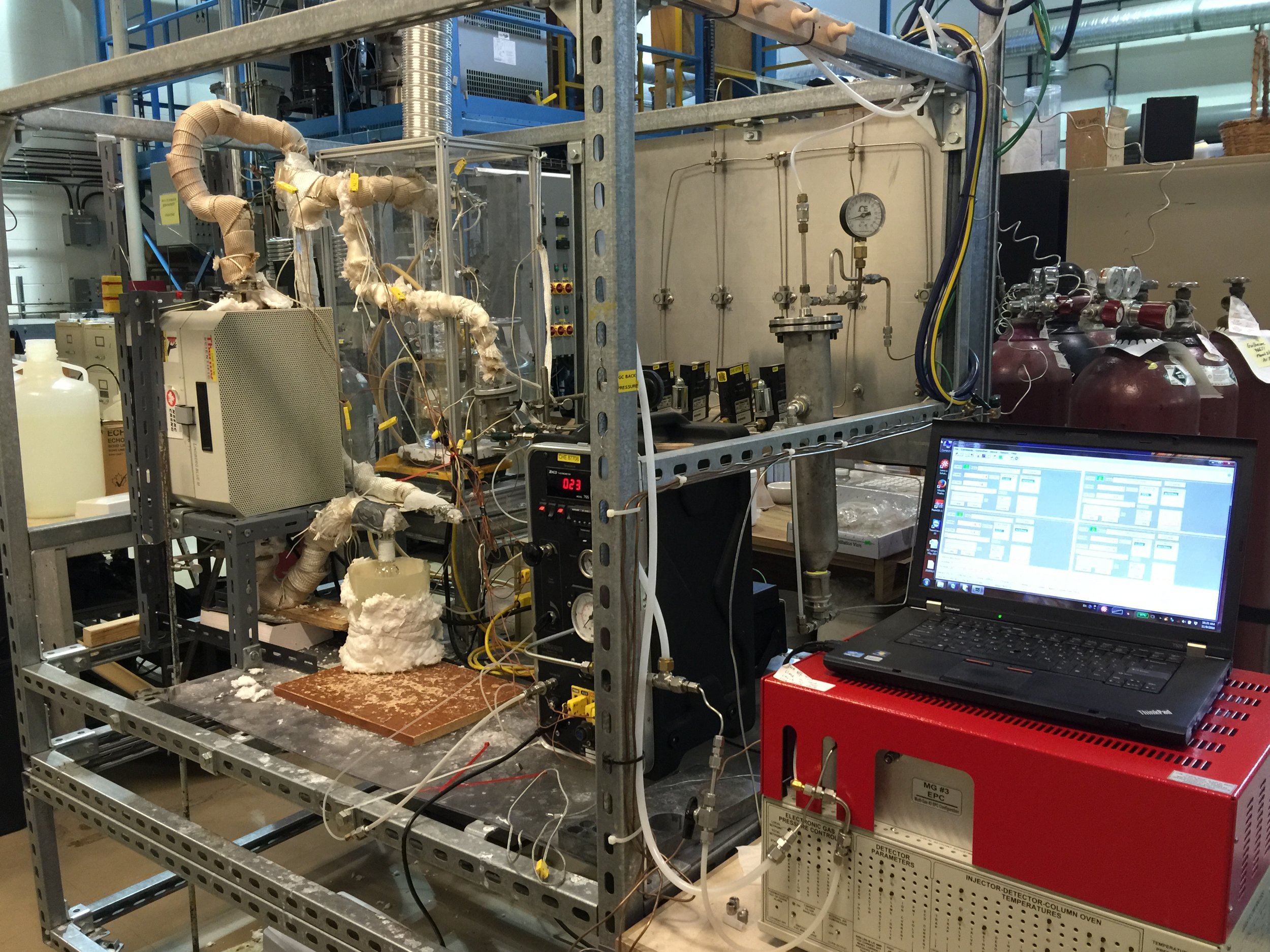

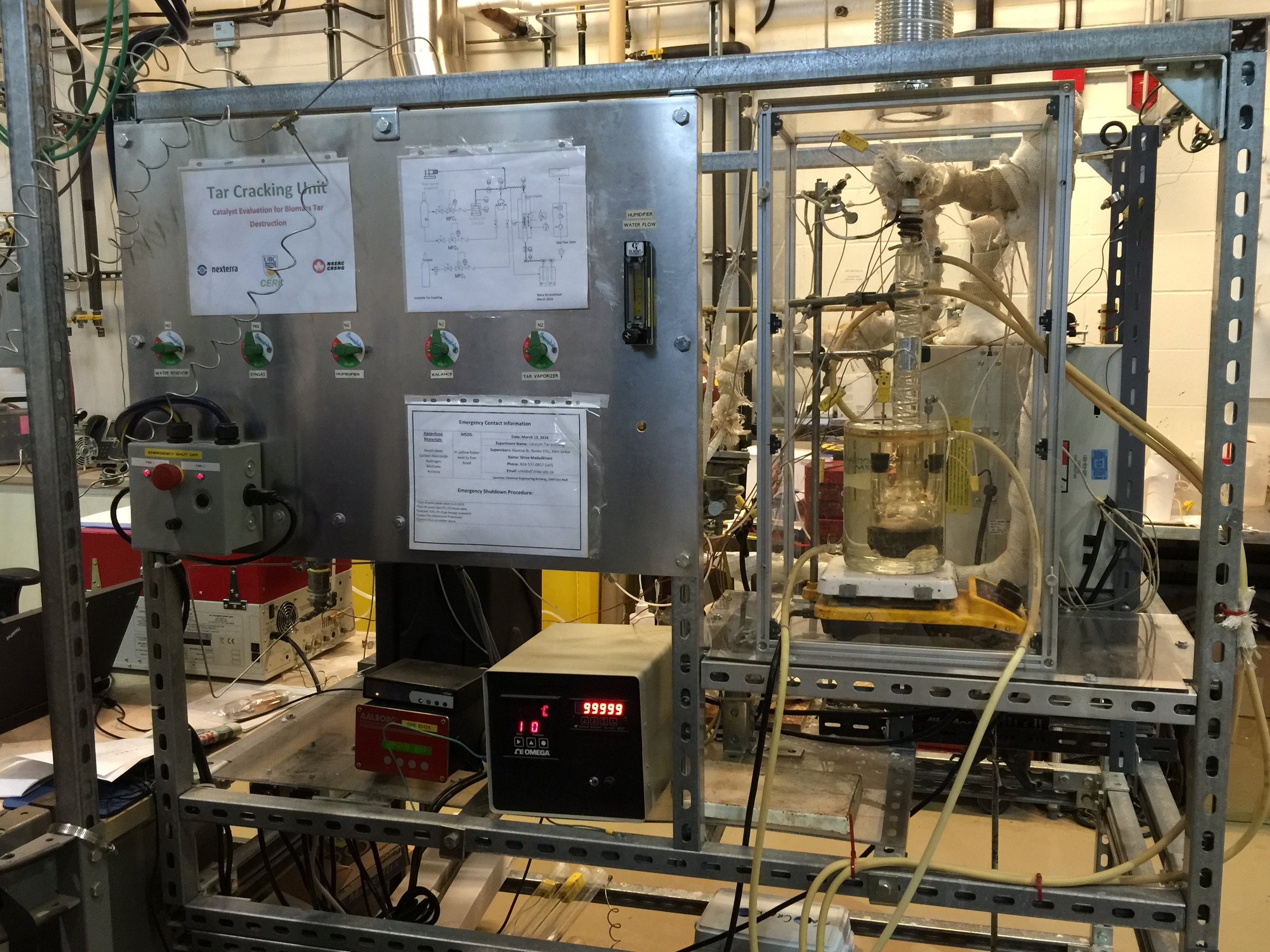

Study on Tar Steam Reforming

Visiting scholar: Dr. Changqing Guo, Associate Professor, Guangzhou Institute of Energy Conversion, Chinese Academy of Sciences

Hosting professor: Dr. Xiaotao Bi, Department of Chemical and Biological Engineering,University of British Columbia

Project introduction:

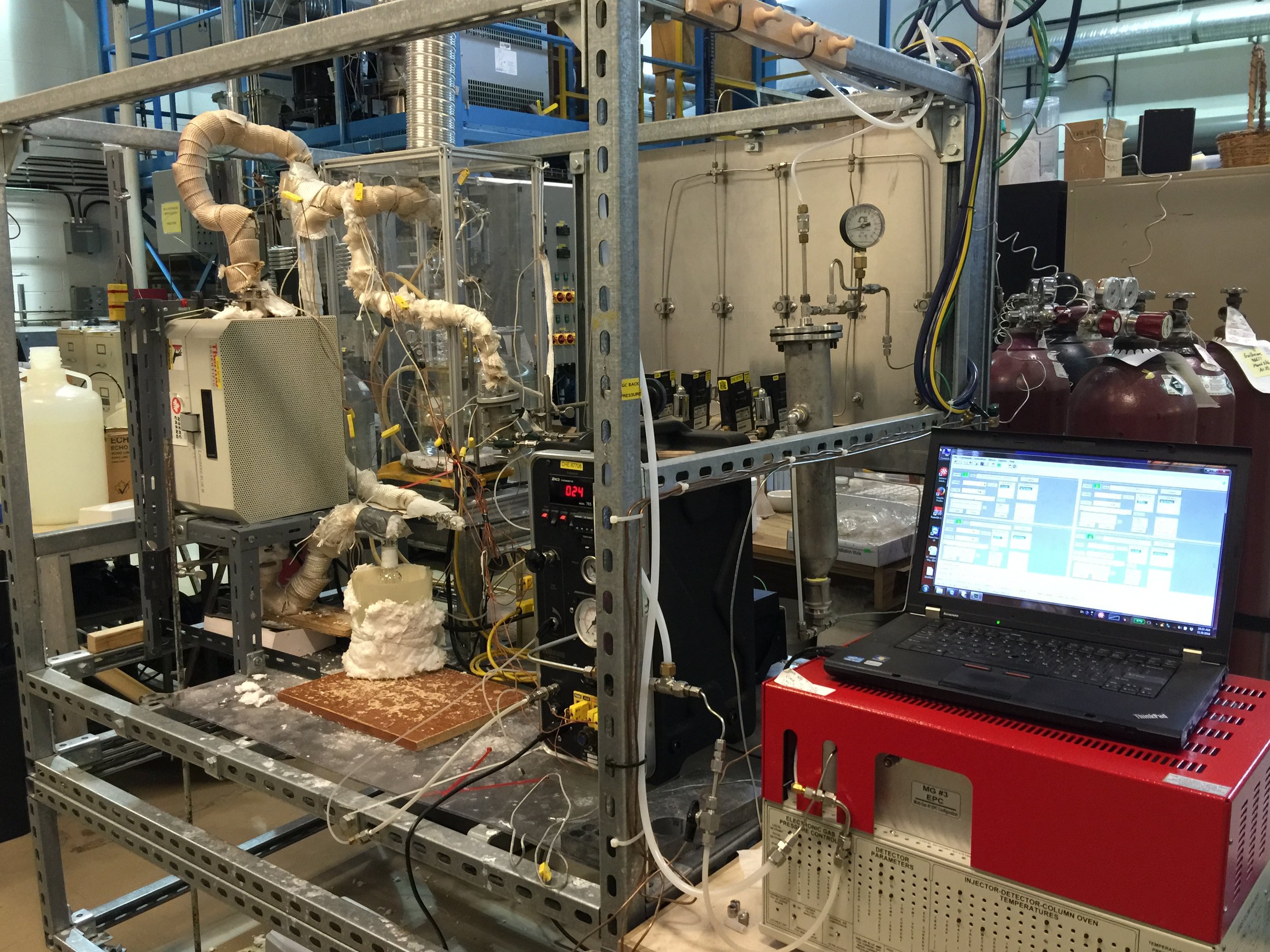

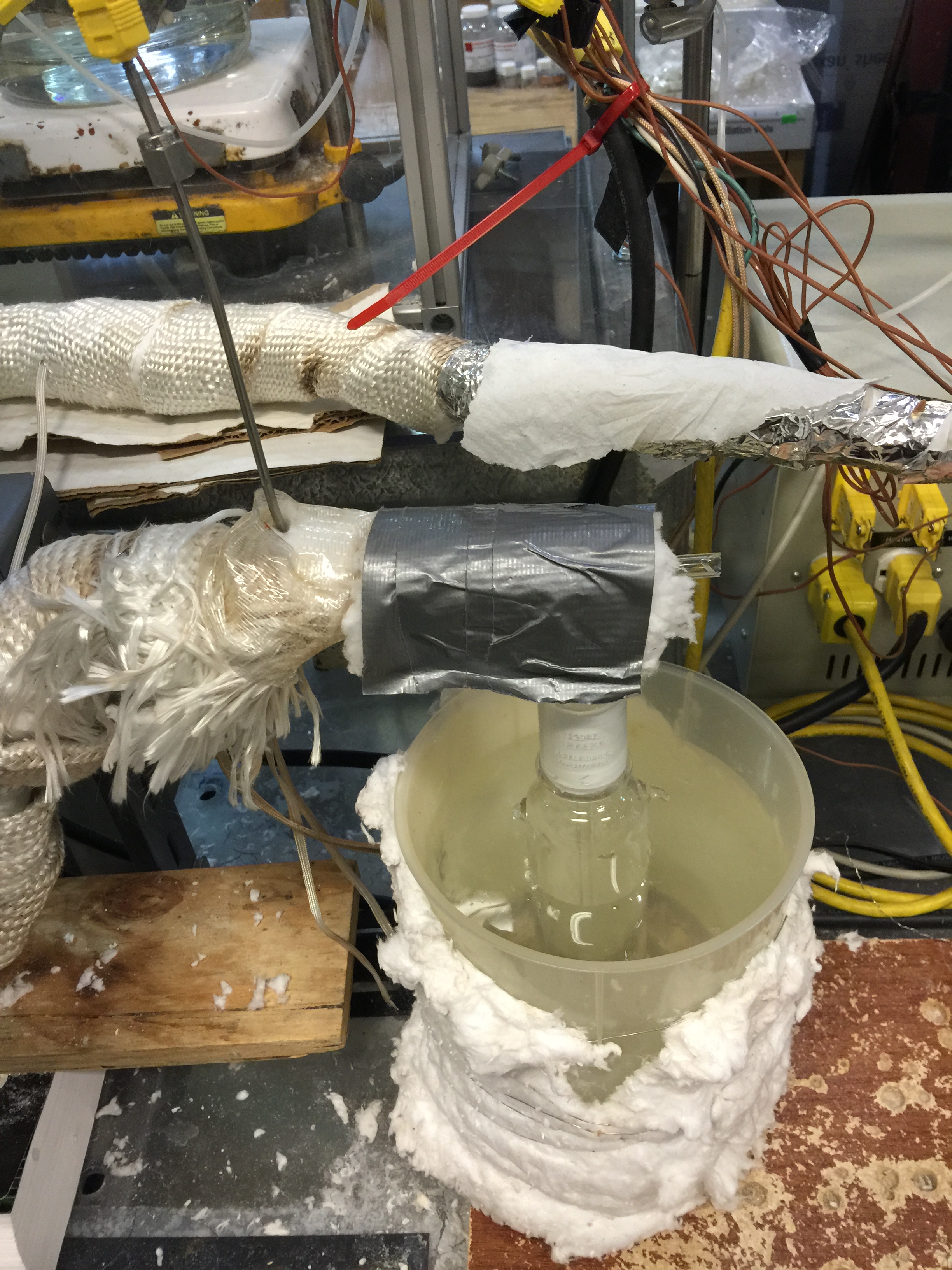

Tar is an unavoidable by-product of biomass gasification process. Tar elimination is considered as one of the major obstacles in the final commercialization of biomass gasification since it can decrease the gasification efficiency and be harmful to human health and environments. Research on tar elimination technology with high energy efficiency is a great challenge in large-scale biomass gasification. In this study, we developed a new and low-cost catalyst, using naphthalene as the model compounds for tar in biomass gasification. Steam reforming experiments under simulated gasification conditions are conducted in a fixed-bed micro-reactor, and the influences of the modification, activation methods, and reaction conditions on the activity and catalyst life are investigated.

Fluidization Triboelectric Separation of Fine Coal

Visiting student: Yong Yang, PhD candidate

Supervisor at home university: Dr. Yaqun He, School of Chemical Engineering and Technology, China University of Mining and Technology

Supervisor at visiting university: Dr. Xiaotao Bi, Department of Chemical and Biological Engineering,University of British Columbia

Project introduction:

Triboelectric separation is a dry separation method for fine particles, and based on the tribocharge difference to achieve density-dominant separation in the electric field. It has a promising application in processing of coal, minerals, fly ash and waste plastics. Fluidization is an ideal tribocharging method, and tribocharge the particles oppositely through collision and rubbing in fluidized bed. The main research contents of the project include the fluidization characteristics of one-component particle and hybrid particles of coal, quartz, calcite and pyrite samples, the effect and mechanism of fluidization causing tribocharge of particles in fluidized bed, the influence and regulation mechanism of electric field on the fluidization behavior of particles, the dynamic model of movement and transportation of tribocharged particle in electric field fluidized bed, establishing the lab fluidization triboelectric separation system to investigate the separation and enrichment pattern of particles tribocharged oppositely in electric field fluidized bed. The key fundamental problems in fluidization triboelectric separation would be resolved in this project, and the research achievements are theoretical guidance and positive to fluidization triboelectric separation of other minerals.

Past Projects

Tar Upgrading via Char Catalysts

Visiting scholar: Dr. Zhiqiang Wu, Lecturer, School of Chemical Engineering and Technology, Xi'an Jiaotong University

Hosting professor: Dr. Naoko Ellis, Department of Chemical and Biological Engineering,University of British Columbia

Project introduction:

Thermochemical conversion of biomass, especially gasification and pyrolysis, can supply syngas for power generation and petrochemical production. However, tar formation during above processes is one of the major challenges to overcome before commercialization. Fouling and blocking can occur in filter module, internal combustion engine and gas turbine under low temperatures. Therefore, reforming of biomass tar is essential for successful implementation of large-scale application of thermochemical biomass conversion. Cracking or reforming biomass tar by char from pyrolysis of = biomass can convert tar to gas or high valued products, such as BTX: benzene, toluene, xylene. In this project, we will prepare biochar and char supported catalysts to reform biomass tars. Pyrolysis of biomass under various preparation conditions (atmosphere, heating rate, final temperature, activation methods) will be investigated in producing effective tar cracking catalyst. Naphthalene will be selected as the model compound of tar, and the thermal and catalytic effects of catalysts on the naphthalene conversion and products selectivity will be conducted in a fixed-bed reactor.

Gas-solid two-phase flow in the liquid injection zone of fluidized bed riser reactors

Visiting student: Zihan Yan, PhD candidate

Supervisor at home university: Dr. Chunxi Lu, College of Chemical Engineering, China University of Petroleum, Beijing

Supervisor at visiting university: Dr. Xiaotao Bi, Department of Chemical and Biological Engineering,University of British Columbia

Project introduction:

A new type of feed injection scheme in which the feed jets realize a countercurrent contact with the catalysts has been proposed. The gas-solid two phase flow behaviors in the proposed and traditional feed injection schemes were investigated experimentally. The distributions of particle concentration and velocity in the feed injection zone of FCC riser have been tested by using a PV6-D analyzer. The dispersion characteristic of feed spray in the riser was studied by a Helium-tracer technique. Then the distribution and the residence time of feed spray were obtained. Besides, the pressure fluctuation in the feed injection zone was tested. The results have shown that there are several advantages in the proposed new type of feed injection scheme. However, deeper understanding of the complex multi-phase flow in the traditional and proposed new type of FCC feed injection schemes still need to be made. First, the residence time and the back mixing of feed spray in the FCC riser will be analyzed. Comparison of the results between the traditional and the proposed feed injection scheme will be made. Second, the pressure fluctuation in the feed injection zone of FCC riser will be investigated. The characteristics of pressure fluctuation in different kinds of feed injection scheme will be analyzed.

Study on CFD simulation of the multisolid pneumatic transport bed

Visiting student: Wenming Liu, PhD candidate

Supervisor at home university: Dr. Hongzhong Li, Institute of Process Engineering, Chinese Academy of Sciences

Supervisor at visiting university: Dr. Xiaotao Bi, Department of Chemical and Biological Engineering,University of British Columbia

Project introduction:

The present study investigated the hydrodynamics of the multisolid pneumatic transport bed (MPTB) using the computational fluid dynamics (CFD) software. The MPTB is a fluidized in which a circulating fluidized bed of fine particles is superimposed on dense-phase fluidized bed of coarse particles. Because of the high rate of mass and heat transfer, the MPTB has been used in various industrial processes, such as the gasification and combustion of coal, petroleum coke and biomass.

Two important parameters are essential to investigate the characteristics of the MPTB, namely the holdup of fine particles and terminal velocity of dense particles. Previous studies mainly focused on the experimental study of the two parameters, and developed empirical correlations. With the development of computational power, the CFD simulation has been an effective method to study the hydrodynamics of the multiphase flows. The complex interaction between the fine and coarse particles and the limited operating range pose a great difficulty to investigate the characteristics of the MPTB by simulation. None of researches have been reported to simulate the two essential parameters of the MPTB. Drag force model is the key to simulate the fluidized bed. However, conventional drag models, such as Gidaspow model, Wen-Yu model and Syamlal-Obrien model, over predict the drag coefficient, leading to the large error of the simulation. Therefore, for the first time, the structure-based drag model developed in our previous study was adopted to simulate the hydrodynamics of the MPTB, and the two essential parameters were validated by the CFD simulation. It will be of prime importance to understand the hydrodynamics and the scale-up of the MTPB.

Effect of AAEMs on biochar oxidation and gasification in O2, CO2 and H2O atmospheres

Visiting student: Qiang Hu, PhD candidate

Supervisor at home university: Dr. Hanping Chen, Dr. Haiping Yang, School of Energy and Power Engineering, State Key Laboratory of Coal Combustion, School of Energy and Power Engineering, State Key Laboratory of Coal Combustion

Supervisor at visiting university: Dr. Xiaotao Bi, Department of Chemical and Biological Engineering,University of British Columbia

Project introduction:

Biomass resources are widely available and have zero emissions therefore have attracted great attention throughout the world. One of the main approaches to utilize biomass is to combust and gasify it into biofuels. During the combustion and gasificaiton process of biomass, the volatiles can be decomposed and released rapidly at high temperature, while the conversion of char is relatively slow. Therefore, it is important to investigate the behavior and reaction mechanism of char, especially for designing and optimizing reactors. At the same time, the content of alkali metal / alkaline earth metal in biomass is high. And it is hard to be volatilized under low temperature thus most of it remains in the biochar. It can act as a catalyst for biochar conversion and it is one of the main reasons that cause boiler fouling and slagging. This project investigates the reaction characteristics and transformation mechanism of biochar in atmospheres of O2, CO2, and H2O, observes the catalytic effect of alkali metal / alkaline earth metal, and analyzes the effect of K, Na, Ca, Mg during the biomass combustion and gasification process.

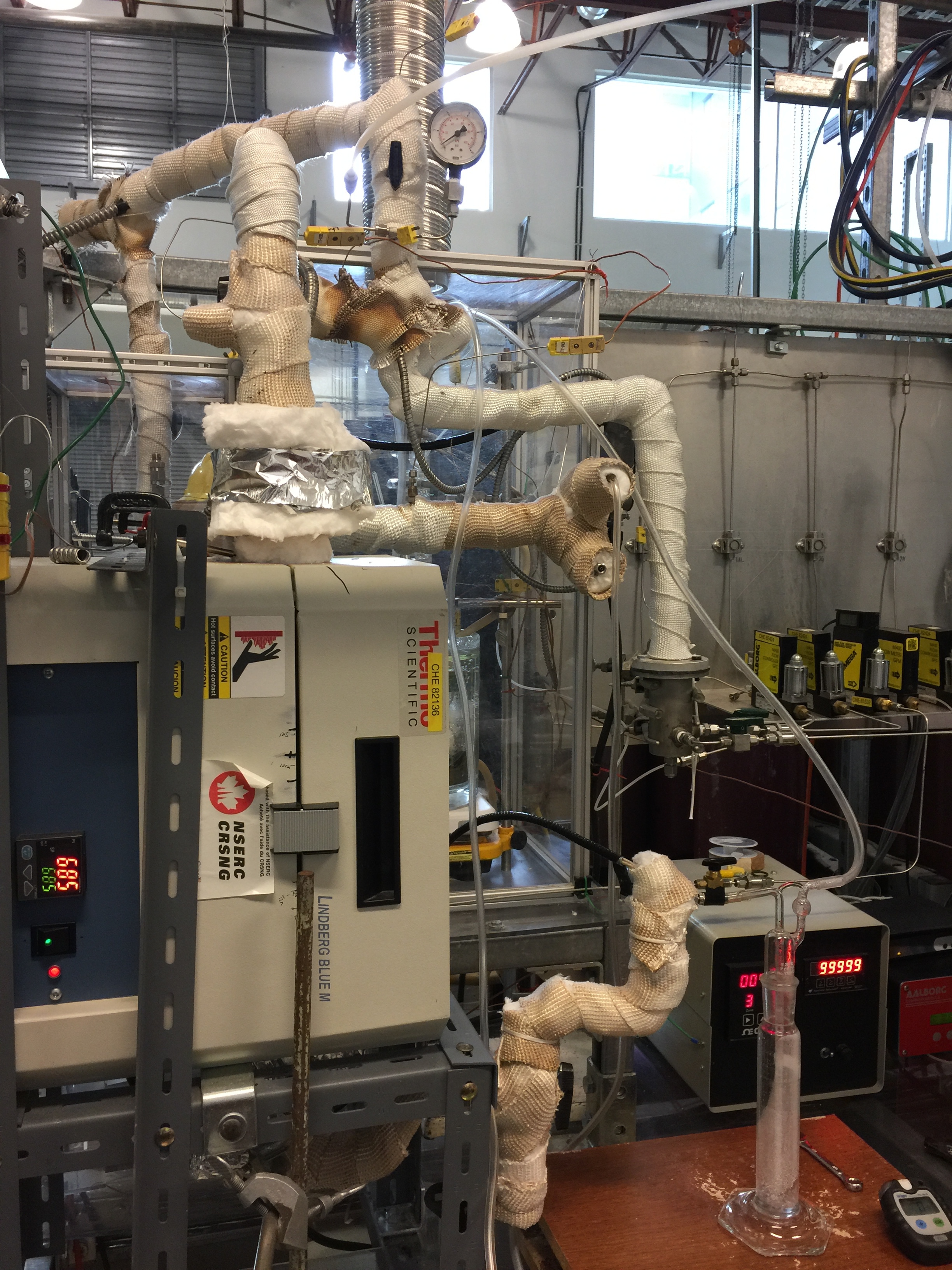

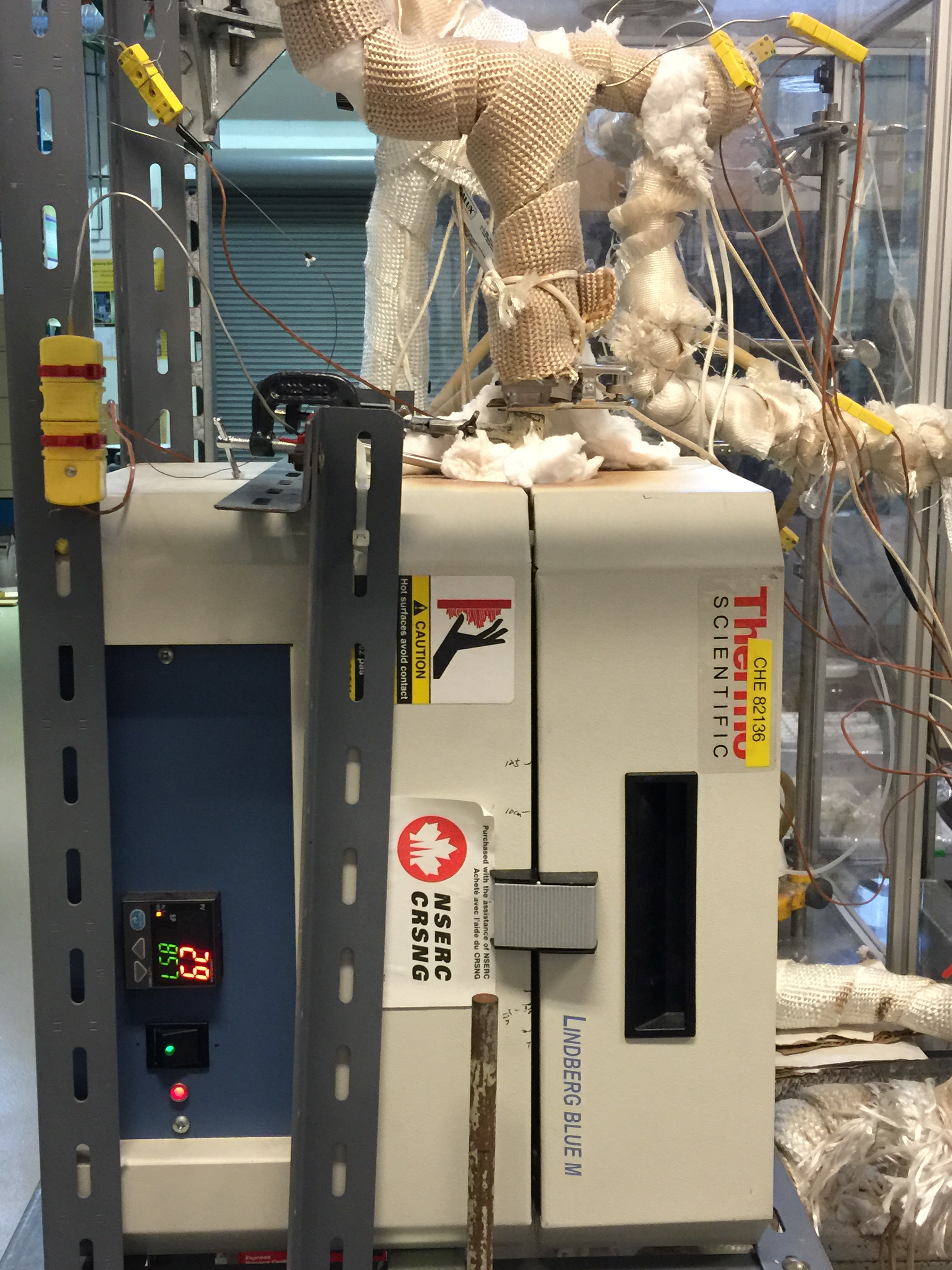

Catalytic Tar Cracking

Visiting scholar: Dr. Zhiguo Zhang, Professor, Department of Energy and Environmental Systems Engineering, Zhejiang University of Science and Technology

Hosting professor: Dr. Xiaotao Bi, Department of Chemical and Biological Engineering,University of British Columbia

Project introduction:

The elimination of tar in biomass gasification processes plays a significant role in improving the efficiency of the gasification system, and the management itself will pose a great effect on the final commercialization. With the condensation of tar, it will not only erode reactors, but also affect the subsequent reaction process. So it is indispensable to handle with the tar through the gasification processes. In this study, we developed a new cheap active catalyst, use naphthalene as the biomass gasification tar model compounds, catalytic tar cracking experiments are reacted in a fixed-bed micro-reactor. Experimental results show that the catalytic activity of the new catalyst is excellent. Therefore, the new catalyst has potential application in industry.

Torrefaction process of biomass in pulse fluidized bed reactor

Exchange student: Chao Qu, Master student

Supervisor at home university: Dr. Jidong Wang, Beijing University of Chemical Technology

Supervisor at visiting university: Dr. Xiaotao Bi, Department of Chemical and Biological Engineering,University of British Columbia

Project introduction:

The survival and development of modern society are highly dependent on energies. At present, most of the energies are fossil energies coming mainly from coal and petroleum. The depositions of fossil energies are not unlimited and not renewable. The continuous consumption over the past centuries has led to the depletion of fossil energies. The petroleum crises in the last century have alerted us that finding renewable energies is urgent for the sustainable development of our society.

Biomass energy, due to its clean and renewable characteristics, can be one of the solutions to replace the fossil fuels. The rapid development in scale and commercialization of biomass energy in recent years demonstrate that biomass energy has a prosperous future and will play an important role in the next energy structure.

Biomasses, however, are structurally heterogeneous, physically non-uniform and hydrophilic with low energy density and usually high moisture content. These characteristics of biomass impose problems in the handling, transportation and storage. Also it is necessary to convert them into high-energy products. For addressing the above problems, biomass can be torrefed to reduce its moisture, to improve its physical properties and to increase its density of energy.

Torrefaction is a thermochemical treatment process which is similar to roasting or mild pyrolysis. In this project, the torrefaction of biomass in a pulse fluidized bed reactor will be studied. Upon torrefaction, the biomass will be converted to a material that has lower moisture content, high energy density and good grindability for efficiently handling, transportation and storage.

The experimental study and numerical simulation on hydrodynamics and mass transfer in novel baffled catalyst stripper

Joint PhD student: Yongshi Liang, PhD candidate

Supervisors: Dr. Chunxi Lu and Professor Yongmin Zhang, China University of Petroleum, Beijing

Co-supervisor: Dr. Xiaotao Bi, Department of Chemical and Biological Engineering,University of British Columbia

Project introduction:

In petroleum refineries, fluid catalytic cracking (FCC) process continuously plays an essential role as a main approach to convert the heavier feedstock to lighter products, such as gasoline and diesel oil. As the primary part in a FCC unit, the reaction-regeneration system adopts a wide flow regime of fluidized beds. The spent catalyst stripper in this system is a typical bubbling fluidized bed reactor. It is designed to use high-temperature steam to recover the light hydrocarbons entrained and adsorbed in interstices and internal pores of the catalyst particles. High efficiency of catalyst stripping can increase the yield of valuable products. Various internal baffles are installed in commercial FCC strippers to enhance gas-solid contact which contributes to a higher stripping efficiency. Disc-donut baffle is commonly installed in commercial FCC strippers. However, problems also exist in the disc-donut stripper. It is criticized for its small flowing area due to the block of the disc and donut baffles resulting in poor operational flexibility. It is also criticized for its large invalid stripping areas i.e. void area beneath the baffle and defluidized area above the baffle. Packed strippers were proved to better address these problems as reported in literature. Their baffles are usually composed of different structural small internals dividing the whole flowing area of the stripper into several or dozens of small units, which effectively lead the gas-solid flow and break the big bubbles into smaller ones. In this pattern, the entire space in the stripper can be utilized which largely eliminates the defluidized area and improves the overall gas-solid contacts at the same time. The objective of this research is to develop a novel packed stripper suitable for FCC unit. Furthermore, comparisons of gas-solid hydrodynamics and mass transfer among different types of strippers will be made through experimental and simulation methods, which intends to investigate the role of baffles in the strippers.